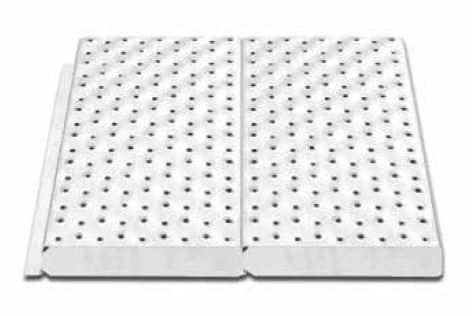

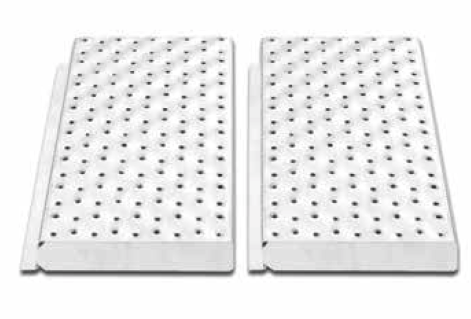

Perforated Metal Planks

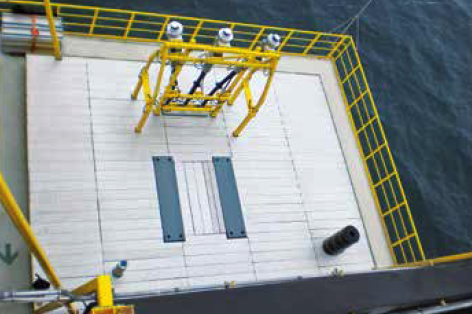

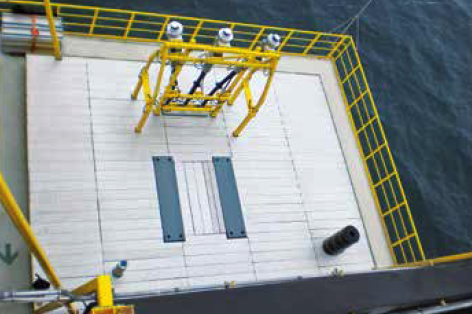

Perforated metal planks can be used on numerous occasions due to their functionality and looks.

Perforated metal planks can be used as work platforms, ramps, façades, grandstands, and much more. They are also used as walkways and supply routes. Our perforated metal planks are highly secure and stable. Furthermore, they can increase safety in your workspace.

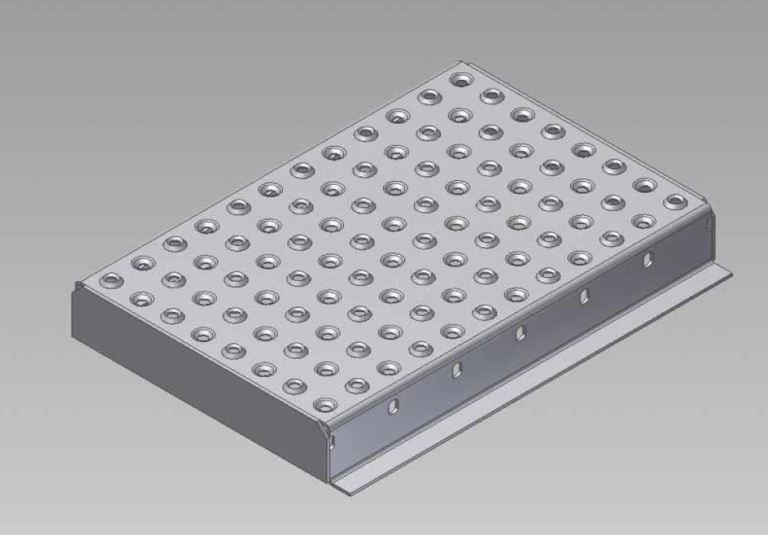

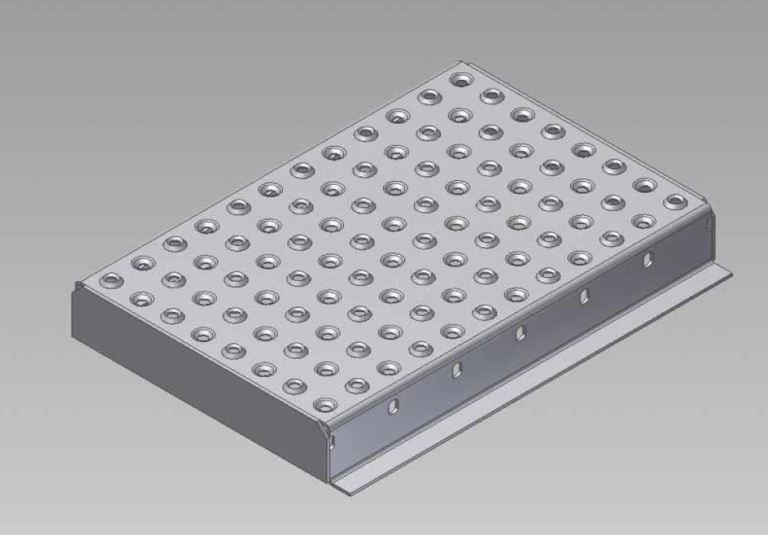

Our perforated metal planks are produced by Lichtgitter, who is known for their high quality. Perforated metal planks are C-shaped profiled and bent construction elements. Perforated metal planks are manufactured on CNC punching machines and roll formers.

We are happy to assist with tailor-made solutions for your company.

Characteristics

- Bridging of large spans

- Cost reduction on substructures

- High slip resistance

- Stable and safe walking and standing areas

- Different surface profiles

- Fast and simple installation

- Considerable production lengths up to 10 m

Available Materials:

• Hot Dipped Galvanized Steel (S 355 JR/J0/J2)

• Stainless Steel

• Aluminum

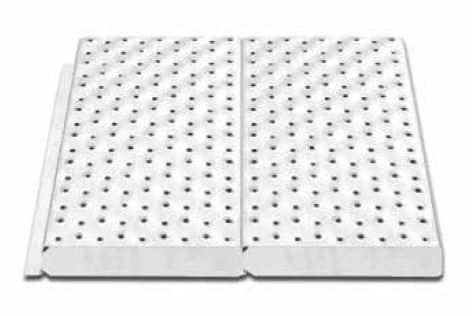

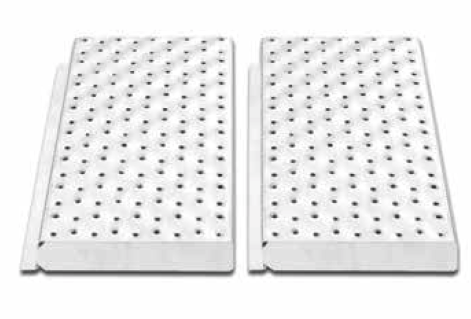

Perforated Metal Planks

Perforated metal planks can be used on numerous occasions due to their functionality and looks.

Perforated metal planks can be used as work platforms, ramps, façades, grandstands, and much more. They are also used as walkways and supply routes. Our perforated metal planks are highly secure and stable. Furthermore, they can increase safety in your workspace.

Our perforated metal planks are produced by Lichtgitter, who is known for their high quality. Perforated metal planks are C-shaped profiled and bent construction elements. Perforated metal planks are manufactured on CNC punching machines and roll formers.

We are happy to assist with tailor-made solutions for your company.

Characteristics

- Bridging of large spans

- Cost reduction on substructures

- High slip resistance

- Stable and safe walking and standing areas

- Different surface profiles

- Fast and simple installation

- Considerable production lengths up to 10 m

Available Materials:

• Carbon Steel S 355 JR/J0/J2

• Stainless Steel

• Aluminum

Flame-retarding Covering

The advanced flame retarding covering BN-OF is developed specifically for avoid oil fires. Energy suppliers are using oil for the cooling of aggregates in transformer units. Normally pans that have to collect the oil are installed beneath the aggregates. The pan should avoid that in case an accident oil could reach the ground and could pollute the groundwater.

There is always a danger that a fire could arise due to the relatively low flashpoint of the oil and the high operating temperature. Bearing this background in mind it is more and more common to make use of fire retarding coverings to limit the chance of a fire in the oil collecting pan. Our fire-retarding covering BN-OF is designet specifically for this purpose.I n case of fire the flames are restrained by the limited air permeability, but not stifled.

- Better and quicker control of the collecting pan

- Shorter switch-off period of the transformer

- Quick possibility to remove the liquid out of the collection pan

- This system would stifle possibly beginning fire

- Serial production – short delivery times

- Existing installations can be rebuilt without problems

- The covering is especially suited for locations where in case of an accident the rescue service cannot be immediately at site