GRP Moulded Gratings

We deliver moulded GRP gratings in all standard types and variations. Moulded GRP gratings are often used for floorings, treads, facades and ceilings.

Our moulded GRP gratings are of top quality and are produced by Lichtgitter. The moulded GRP gratings have very good resistance to corrosion, can withstand very large loads, and require almost no maintenance.

GRP moulded gratings in panels and treads are available in stock for fast delivery. We can also supply tailor-made products for your company. The appropriate mould is selected based on the desired grating type, height, pitch, and bar width. We also adapt the design and colors to your needs.

GRP Moulded Gratings

We deliver moulded GRP gratings in all standard types and variations. Our moulded GRP gratings are of top quality and are produced by Lichtgitter. The moulded GRP gratings have very good resistance to corrosion, can withstand very large loads, and require almost no maintenance.

GRP moulded gratings in panels and treads are available in stock for fast delivery. We can also supply tailor-made products for your company. The appropriate mould is selected based on the desired grating type, height, pitch, and bar width. We also adapt the design and colors to your needs.

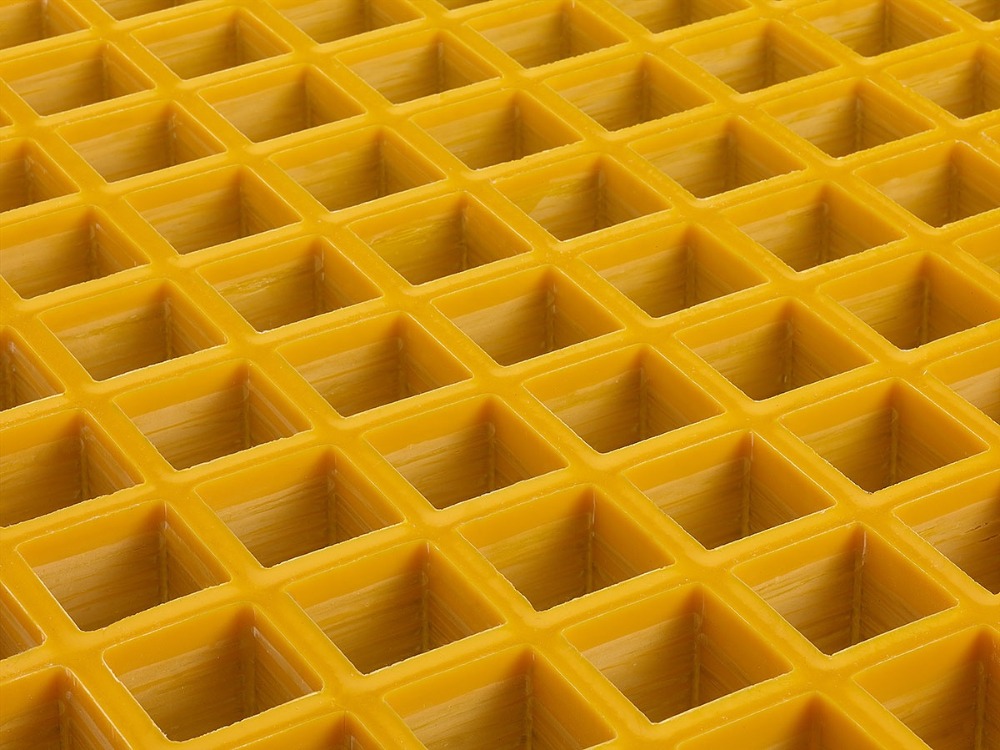

Gratings with Concave Surface

Type: GRP-K

A concave surface is defined as a surface of the plane which curves inward during curing. The resulting web edges ensure high slip resistance. This surface achieves the slip resistance rating group R13 according to BGR 181.

The grating type GRP-K is available in various mesh widths, from standard to narrow pitches and in various grating heights, for example, as heavy-duty gratings available with a height of 50 or 60 mm from stock.

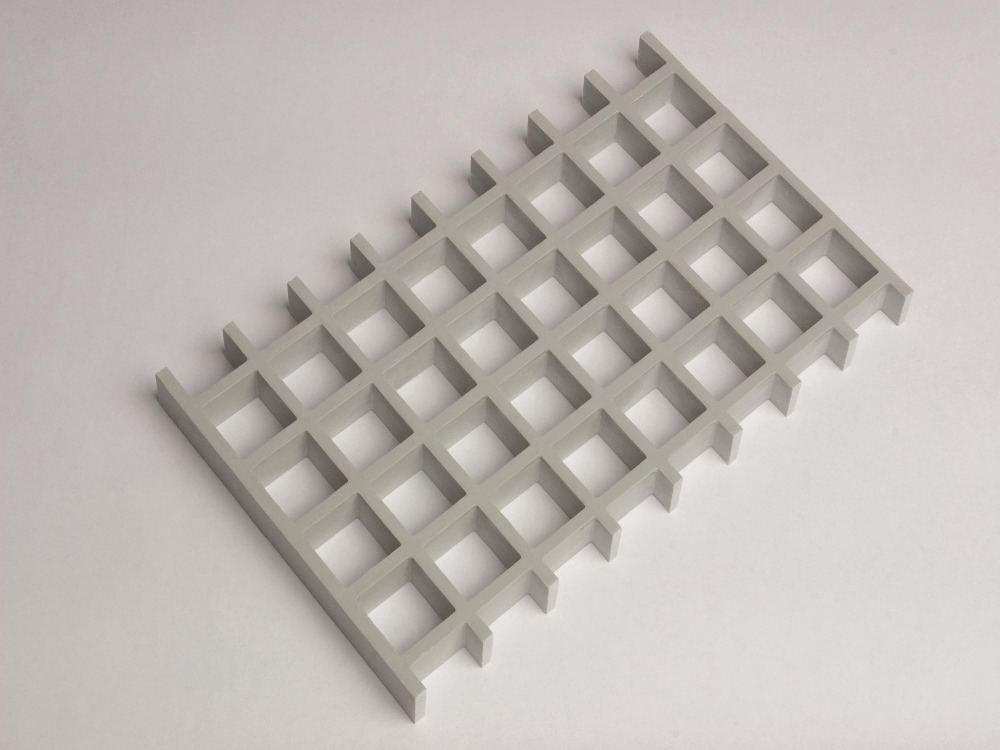

Gratings with Polished Surface

With a ground surface, the concave surface of the GRP gratings is sanded after curing. This creates a smooth surface that can be subsequently sealed.

Type: GRP-G

The grating model GRP-G is available in different strengths, heights, and mesh widths so that a wide range is guaranteed.

Type: GRP-S

The grating type GRP-S is used for very strong gratings.

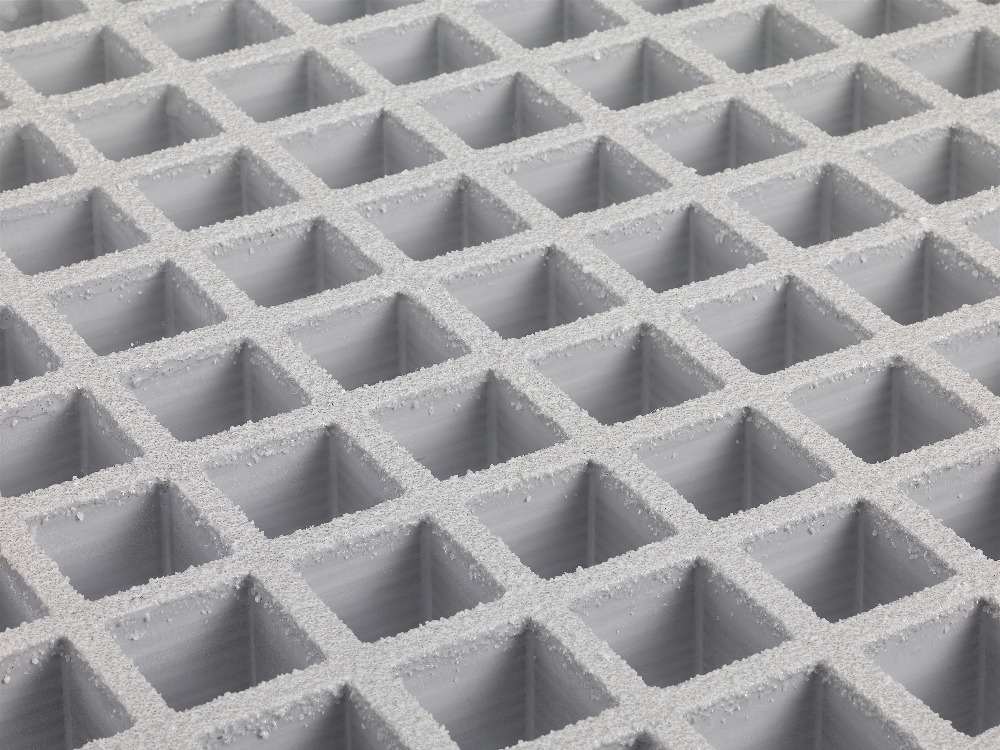

Gratings with a Sanded Surface

Also, the GRP gratings can be additionally supplied with a sanding. This makes higher anti-slip rating groups possible. The sanding is applied to the surface in conjunction with a resin. A distinction is made between a coarse corundum and a finer quartz coating.

Type: GRP-BK

The corundum sanding is a sanding with sand grain size between 0.5-1.0 mm. The anti-slip rating group R13 is achieved and therefore often used outdoors. Furthermore, this sanding is used in industry when lubricants and oils are present.

Type: GRP-BQ

The quartz sanding uses a sand grain size between 0.1-0.4 mm. Through the use of the finer quartz sand grains, the gratings are also suitable for the barefoot area and achieves the anti-slip rating group R 12.

Gratings with a Closed Surface

Type: GRP gratings closed

A GRP plate is laminated onto gratings with a closed surface. The plates are mostly sanded.

Type: GRP gratings sandwich

Two-sided closed GRP grating. A GRP plate is laminated both on the top and the bottom. The surface can be sanded to be anti-slip. Such a floor covering is suitable especially in areas where tight flatness tolerances are required.

Type: GRP gratings closed, chequer plate surface

This is another design variant of the closed GRP grating. Instead of a sanded GRP plate, a so-called chequer plate look is used, similar to that seen in the steel sector.

Typical applications:

- Industrial floorings, e.g. for the chemical / petrochemical industry, power plant industry and offshore applications

- Platforms, ramps, entrances and crossings

- Gratings with on top welded chequer plates for work platforms, gratings as a load-bearing element

Treads

GRP stair treads are delivered with a black-colored and sanded nosing bracket 60 x 60 x 8 mm in the width dimensions 617 mm, 807, 997 mm, and 1226 mm as standard. With tread depths of 236 mm, 274 mm, and 312 mm, we can guarantee closed meshes. Differing dimensions can also be manufactured on request, however, it is to be noted that open edges are possible.

Nosing bracket

The sanded and black-colored nosing bracket visually marks the front edge particularly advantageously. This contributes substantially to the safety. It also serves as the structural reinforcement to meet the load requirements. In areas where nosing bracket is not possible due to the construction, the nosing bracket can be implemented from a flat GRP material. This has a black sandy surface. Can also be delivered with yellow color.

In areas where, for constructive reasons, a bracket is not possible or necessary, the nosing edge can be implemented from a GRP flat material in black, sanded.

Fastening

The GRP treads are installed on existing customer supports as standard and screwed with the direct screw connection BU13840K. Optional side plates are available from a GRP bracket. With treads from a width of 807 mm, a nosing bracket is required from a static perspective.